Home--- Services---Plastic injection Molding

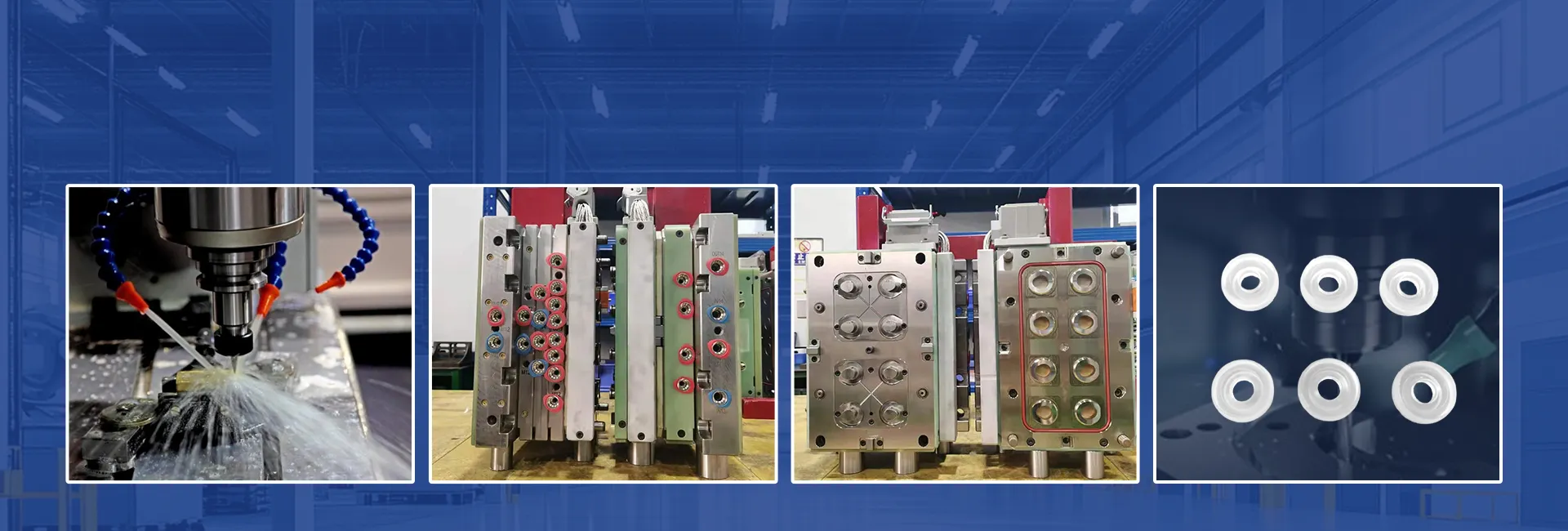

we pride ourselves on maintaining a state-of-the-art injection molding workshop designed to ensure precision, quality, and efficiency in the production of molds and products. Our commitment to excellence is reflected in our clean and organized environment, which is essential for delivering superior outcomes.Key Features of Our Injection Molding Workshop:

**Cleanroom Standards**

Our workshop adheres to strict cleanroom protocols, ensuring that all processes are conducted in a controlled environment. This minimizes contamination and guarantees the integrity of both molds and finished products .

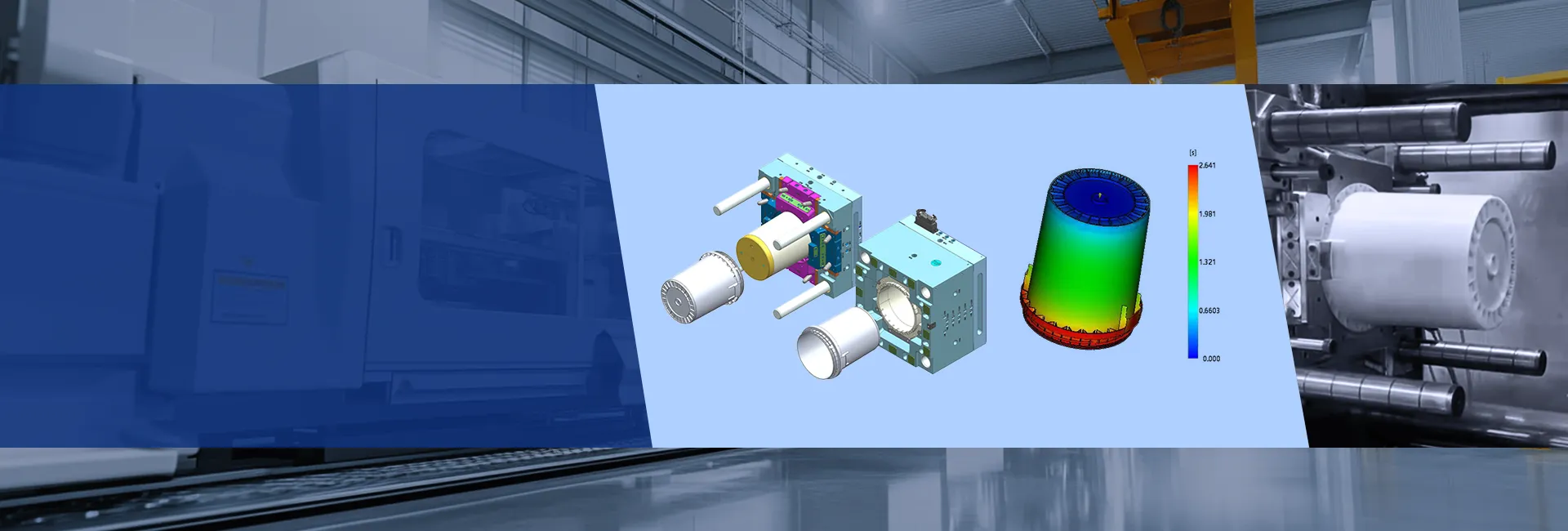

**Advanced Injection Molding Machines**

Equipped with the latest technology, our injection molding machines provide high precision and versatility. These machines are capable of handling a wide variety of materials, allowing us to create complex geometries and intricate designs to meet diverse customer needs.

**In-House Trial Capabilities**

We conduct comprehensive in-house trials for both molds and product production. This allows us to fine-tune designs and processes before full-scale manufacturing, ensuring optimal performance and reducing lead times. Our team can quickly iterate on designs, making adjustments as needed for the best possible results.

**Skilled Workforce**:

Our highly trained technicians and engineers are dedicated to maintaining the highest standards of quality and safety. Their expertise ensures that every aspect of the injection molding process is meticulously executed, from mold design to production.

**Quality Control Measures**

We implement rigorous quality control procedures at every stage of production. Our workshop is outfitted with advanced testing equipment to ensure that all products meet stringent quality standards and customer specifications.

**Flexible Production Runs**

Whether it's a small batch or a large-scale production run, our workshop is equipped to handle projects of varying sizes

Injection Shop

Hello! What do you need help with?